The Wonders of Laser Cutters

There are a few tools that every makerspace will probably have: a 3D Printer, a CNC Router, and a Laser Cutter. Our space has 2 out of 3, but that last one, the Laser Cutter, is something our members and community has wanted access to for a long time. There is certainly a lot a maker can do with a 3D Printer and a CNC Router, but the the 3D Printer is limited to plastics, and the CNC Router takes some finesse to get good results. A Laser Cutter is more hobbyist and beginner friendly for cutting out designs for assembling or engraving on a wide variety of materials. It’s an excellent design tool for students and professionals. You can see a bunch of sample projects in this video from Origin Laser.

That’s why we’re organizing a fundraising campaign through our website! By going to this page, or scrolling down a little, you can donate money towards the purchase of a laser cutter for the makerspace! There are various donor levels to say thanks and allow those who donated to have access to the laser cutter once we have it. Please check it out today and donate if you can! Even a dollar will help!

[give_form id=”4400″]

More CNCs in progress

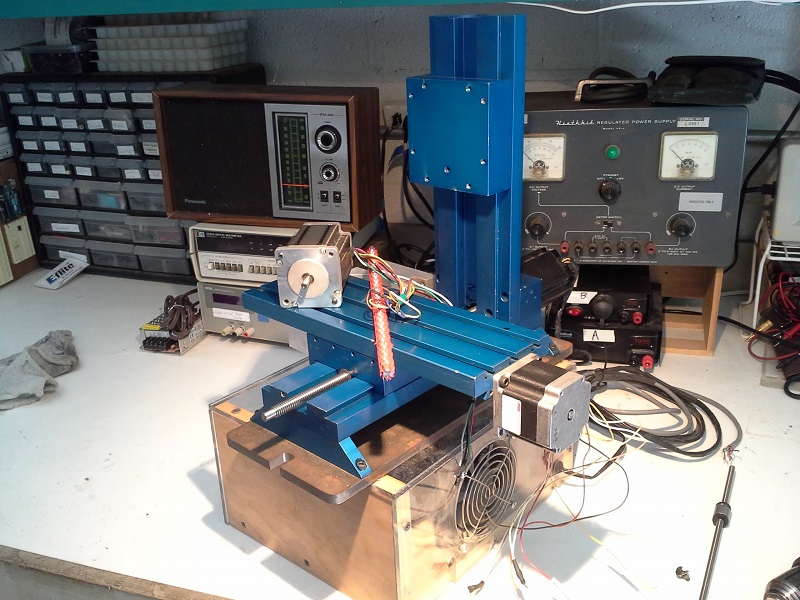

Paul and Alex are working on getting this thing working! When it’s all together it should be a CNC Mill, great for making all your metal parts.

This hardware was donated awhile back and like many projects collected a healthy patina until this week. When we took it out of its dusty resting place, we did a assessment of what it needed. Turns out most of the machine was there, but it needed one leadscrew for the Z axis, and a couple more motors.

Luckily for us we like to save parts for a rainy day, and we happened to have TWO leadscrews that were bigger than the original and TWO motors. Paul did some machining to the various parts to accommodate the new leadscrews and nuts, which took a half hour on the Bridgeport. The new nuts were epoxied in place (the originals were threaded in), and waited for it to dry.

Now most of the hardware is in place, the rest is electronic! It came with a HobbyCNC control board and a power supply, but we need wire for the motors. We’ll likely also need end-stop switches. And the final crucial component is the spindle… which it did not have. May have to scavenge through the parts bins for a good spindle!

If you’d like to contribute to this build, you can make a donation here to help us get new parts!

[give_form id=”4852″]

What Wood Andrea Works With

Our Wood Shop is probably the most popular part of the Makerspace. It’s pretty obvious why, out here there are tons of hobbyists and professionals working with the wood that is in great supply. There’s also just something about wood working and the culture of New England that goes well together. The DIY spirit is well-entrenched in the people around here.

Below are some photos of projects one of our members has put together with the aid of our Wood Shop space and tools. These are all works by sculptor and artist Andrea Thompson. You can see more of her work on andreathompsonart.com. Andrea comes to our wood shop infrequently, but when she does it’s usually with a fairly big project. The boards you see below were sanded down on our Performax Drum Sander to get them good and cleaned up. With most of them being over 5 feet tall, it made things much easier to feed the boards through the sanding machine compared to palm sanding them. The tall planks themselves are from oak beams salvaged from the Boston Navy Yard after 200 years of underwater storage.

She has dubbed these pieces A Live Oak Dreams of Going to Sea.

These are part of another series she made with tools from our wood shop. The boats are made of cedar and had their rough shapes cut out on the bandsaw; some of the cedar came from our handy neighbors at Ricci Lumber.

She calls this series The Unlikely Vessels

Teach a Course!

Do you have some skills you could share with the Port City Makerspace Community? Teaching a course is a great way to build community and make a little money on the side. If you have a course in mind just fill out this form and we will get the process started to make you the next member of our instructor team at Port City Makerspace!

Curious about pricing and how we pay instructors? Read this explanation.

Featured Member: Scott

Scott Winchester is a meticulous craftsman. He makes everything to the highest standard he knows how. You simply need to look at his final product to know that he’s not one to cut corners and is willing to spend the time it takes make something to the quality he wants it to be. Although he hasn’t been a member for long Scott dove right in at Port City Makerspace as an instructor and the inaugural member of our Space Cadet Volunteer program and single-handedly mans the shop most sundays. Scott teaches our blacksmithing and forging classes and our tool sharpening classes. You can find his work on etsy under the username Stonewind.