CNC Plasma Cutter: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

MarthaBoyd (talk | contribs) No edit summary |

||

| (17 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

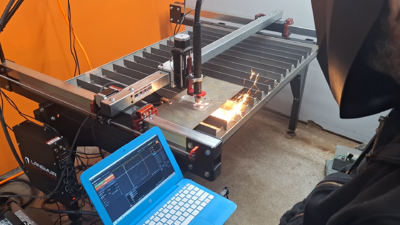

[[File:cncplasmacutter.png|400px|thumb|Langmuir CNC Plasma Cutter]] | |||

==About our machine== | ==About our machine== | ||

*Model: | *Manufacturer: Langmuir Systems | ||

*Cutting Area: | *Model: CrossFire Pro | ||

*Cutting Area: 48.25” (X) x 33.3” (Y) x 2.75" (Z) + 3” Manual Height Adjustment | |||

*Computer: | *Computer: | ||

*Control Software: | *Control Software: FireControl | ||

*Plasma Cutter: Hypertherm Powermax45 Sync Model# 088184 | |||

*Max cutting capacity: 5/8" thick steel | |||

==Guides and Manuals== | |||

*General | |||

**[https://www.langmuirsystems.com/safety Plasma Safety] - Manufacturer's safety warnings for plasma cutting. | |||

*Software | |||

**[https://www.langmuirsystems.com/firecontrol/guide Cut With FireControl] - Manufacturer's guide to software use. | |||

**[https://docs.google.com/document/d/1u3rAuRWWIrONUExP6ONZ9EOy3wD1-y26rPdyytBEiVI/edit?usp=sharing Fusion Outline] (for class) | |||

*User Guides | |||

**[https://www.langmuirsystems.com/introduction Introduction] | |||

**[https://www.langmuirsystems.com/plasma CNC Plasma] | |||

**[https://www.langmuirsystems.com/software Software Workflow] | |||

**[https://www.langmuirsystems.com/software/fusion CAD/CAM with Fusion360] | |||

**[https://www.langmuirsystems.com/firecontrol/guide Cut with FireControl] | |||

**[https://www.langmuirsystems.com/software/sheetcam CAM with SheetCAM] | |||

**[https://www.langmuirsystems.com/thc/guide LS-Torch Height Controller Guide] | |||

*Hypertherm45 Sync | |||

**[https://drive.google.com/file/d/1WIbmiCK-XQeKN51yuDPLWSBvQOnZUsa-/view?usp=drive_link Operator Manual] | |||

**[https://drive.google.com/file/d/1j29hIJ0AO5Y6iPPt0vm574MrJJh7Dy2C/view?usp=drive_link Cut Charts Guide] | |||

**[https://drive.google.com/file/d/1KPcf_eG64azRM46mJGcRapfbDzzs1fKw/view?usp=drive_link Mechanized Cutting Guide] | |||

*Hardware | |||

**[https://www.langmuirsystems.com/pro/assembly CrossFire Pro Assembly Guide] | |||

==Standard Operating Procedures== | |||

'''Safety Precautions''' | |||

1. Personal Protective Equipment (PPE): | |||

* Wear safety glasses with side shields or a face shield. | |||

* Use flame-resistant gloves and clothing. | |||

* Turn on air filter system | |||

* Turn on exhaust fan | |||

2. Work Area Safety: | |||

* Ensure the work area is clean, dry, and free of flammable materials. | |||

* Maintain adequate ventilation to avoid inhalation of fumes and gases. | |||

* Know the location of the fire extinguisher. Next to the Auto Bay access door. | |||

3. Equipment Safety: | |||

* Inspect the plasma cutter, CNC table, and all connections for damage before use. | |||

* Ensure the plasma cutter is properly grounded. | |||

* Do not operate the equipment if any safety guards or covers are missing or damaged. | |||

'''Equipment Setup''' | |||

1. CNC Table Setup: | |||

* Empty Air Compressor of water: Slowly, partially open the ball valve at the base of the air compressor. Allow water to escape. When water stops coming out, close the valve. | |||

* Run Extension Cord for Power | |||

* Power On: Turn on the Langmuir Systems Crossfire Pro CNC table. | |||

* Software Initialization: Launch the CNC control software (e.g.,FireControl) on the connected computer. | |||

* Home the Machine: Use the software to home the machine, ensuring | |||

* the torch is in the correct starting position. | |||

* Material Placement: Securely clamp the material to be cut onto the | |||

* CNC table, ensuring it is flat and properly aligned. | |||

2. Plasma Cutter Setup: | |||

* Power On: Turn on the Hypertherm Powermax 45 SYNC plasma cutter. | |||

* Air Supply: Ensure the air compressor is on and supplying clean, dry air at the recommended pressure (typically 85 PSI). | |||

* Power Setting: Set the Amps to the recommended setting found in the Cut Chart | |||

* Ground Clamp: Attach the ground clamp to the material being cut, ensuring a good electrical connection. | |||

3. Software Configuration: | |||

* Load Design: Import or create the design file in the CNC control software. | |||

* Material Settings: Configure the material type and thickness in the software to match the cutting parameters. | |||

* Cut Parameters: Set the appropriate cut speed, amperage, and pierce height based on the material and plasma cutter specifications. | |||

'''Operation''' | |||

1. Pre-Cut Check: | |||

* Verify Material is Grounded | |||

* Test Run: Perform a test run without the plasma cutter on to ensure the torch follows the correct path. | |||

* Safety Check: Ensure all safety equipment is in place and the work area is clear. | |||

2. Start Cutting: | |||

* Initiate Cut: Start the cutting process from the CNC control software. | |||

* Monitor Process: Keep an eye on the cutting process to ensure everything is operating correctly. | |||

* Be prepared to pause or stop the machine if any issues arise. | |||

3. Post-Cut Procedures: | |||

* Power Off Plasma Cutter: Turn off the Hypertherm Powermax 45 SYNC plasma cutter. | |||

* Remove Material: Carefully remove the cut material from the CNC table, ensuring it is cool enough to handle. | |||

* Clean Up: Remove any slag or debris from the CNC table and work area. | |||

* Inspect Cuts: Check the quality of the cuts and make any necessary adjustments to the settings for future cuts. | |||

'''Maintenance''' | |||

1. Post Use Maintenance: | |||

* Clean the Table: Remove any metal shavings, dust, or debris from the CNC table. Ensure that the Gantry,Rails and Screws are clean. Apply WD-40 to the screws. | |||

* Inspect Torch: Check the plasma torch for wear and damage. Replace consumables as needed. | |||

* Check Air Filter: Inspect and clean the air filter on the plasma cutter. | |||

2. Weekly Maintenance: | |||

* Lubricate Moving Parts: Apply lubrication to the CNC table’s moving parts as recommended by the manufacturer. | |||

* Inspect Cables and Hoses: Check all cables and hoses for wear, cracks, or damage. | |||

3. Monthly Maintenance: | |||

* Software Updates: Check for and install any updates for the CNC control software. | |||

'''Emergency Procedures''' | |||

1. Fire: | |||

* Immediate Action: Use a fire extinguisher to put out the fire if it is safe to do so. | |||

* Evacuate: If the fire cannot be controlled, evacuate the area and call emergency services. | |||

2. Equipment Malfunction: | |||

* Power Off: Immediately turn off the CNC table and plasma cutter. | |||

* Inspect: Inspect the equipment for the cause of the malfunction. | |||

* Report: Report the issue to a supervisor or maintenance personnel. | |||

* Neil Rudnick – neil@portcitymakerspace.com | |||

3. Injury: | |||

* First Aid: Provide first aid if trained to do so. | |||

* Seek Help: Call for medical assistance if the injury is serious. | |||

'''Documentation''' | |||

* Report Issues: Document any issues or malfunctions and report them to the appropriate personnel. Neil Rudnick – neil@portcitymakerspace.com | |||

Training | |||

* Operator Training: Ensure all operators are trained on the safe and proper use of the Langmuir | |||

* Systems Crossfire Pro and Hypertherm Powermax 45 SYNC. | |||

* Refresher Training: Provide periodic refresher training to keep operators up-to-date on safety and operational procedures. | |||

==Important Notes== | ==Important Notes== | ||

*Use welding goggles or a welding helmet when using this tool. It creates bright arcs that can damage your eyes. | |||

*Use gloves when handling materials. Edges can be sharp, and recently cut metals will be hot. | |||

*When pieces are cut free from the main material, they may shift and fall into the table, or they may tilt upwards and potentially collide with the nozzle as it moves. Stop the machine if it is at risk for colliding in this way. | |||

*Check the manual for the plasma cutter to determine which nozzle and what settings to use for your material type and thickness. | |||

*The water table needs to be changed every 1-2 weeks depending on usage. | |||

**When draining, DO NOT allow metal particulate to go down the utility sink. Filter it out with a cheese cloth or scrap fabric and toss in the garbage. | |||

==Consumables== | |||

*[https://www.hypertherm.com/en-US/hypertherm/powermax/powermax45-sync/#torches-and-consumables Torch tips] | |||

**[https://store.cyberweld.com/products/hypertherm-smartsync-cartridge-45-a-mechanized-cutting-gray-428925 45 A 428925 - Cyberweld] | |||

**[https://store.cyberweld.com/products/hypertherm-smartsync-cartridge-30-45-a-finecut-mechanized-cutting-gray-428926 FineCut mechanized cutting 428926 - Cyberweld] | |||

**[https://store.cyberweld.com/products/hypertherm-smartsync-cartridge-ohmic-ring-kit-428895 Ohmic ring kit 428895] | |||

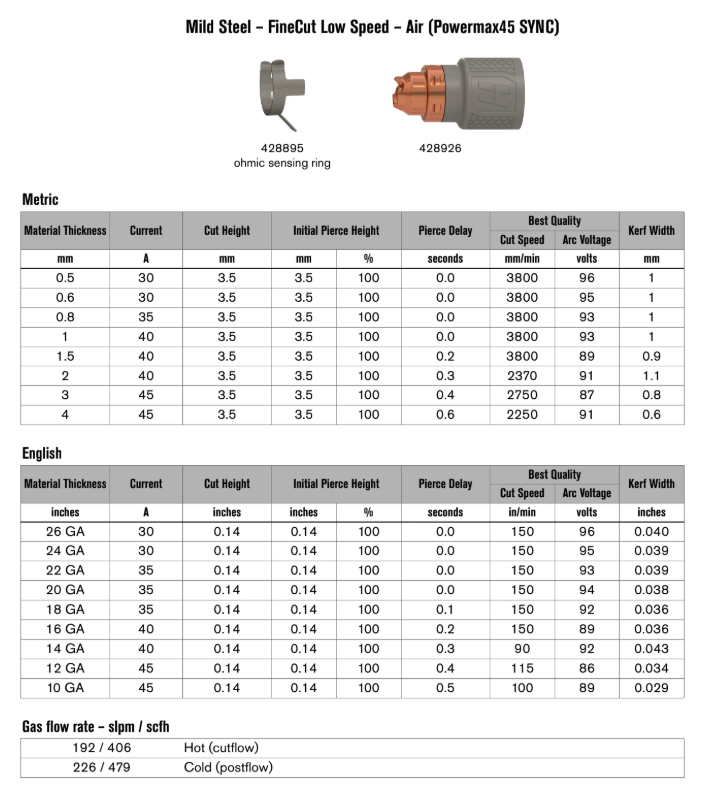

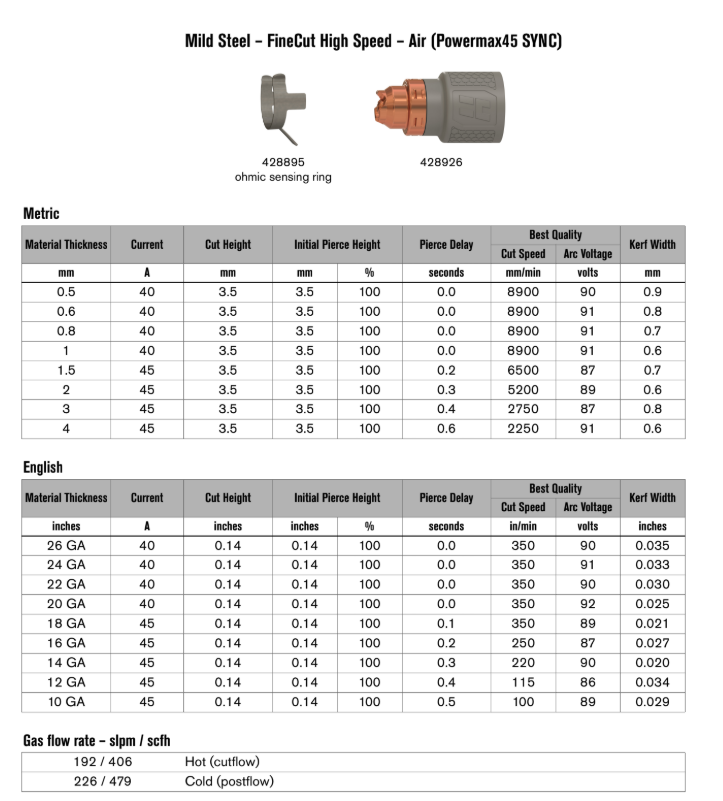

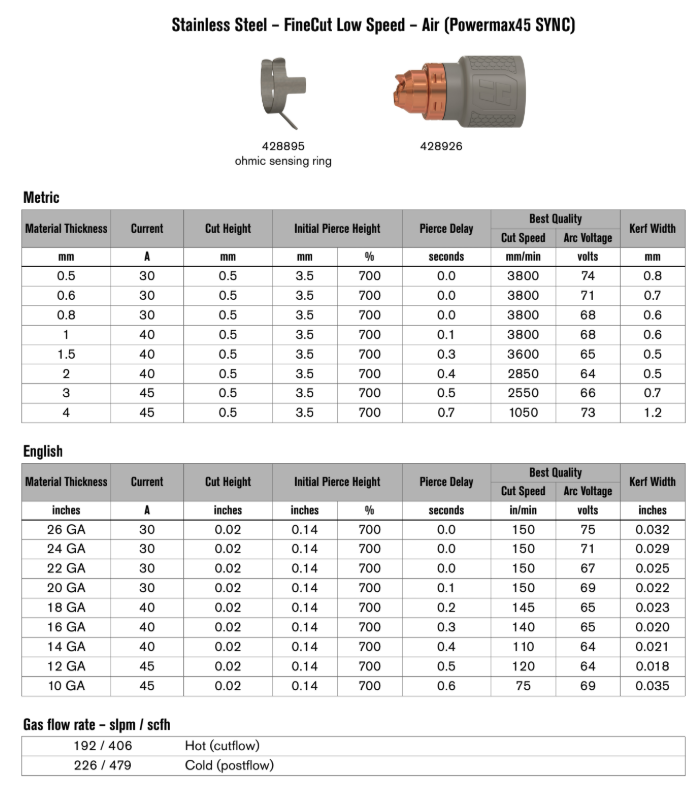

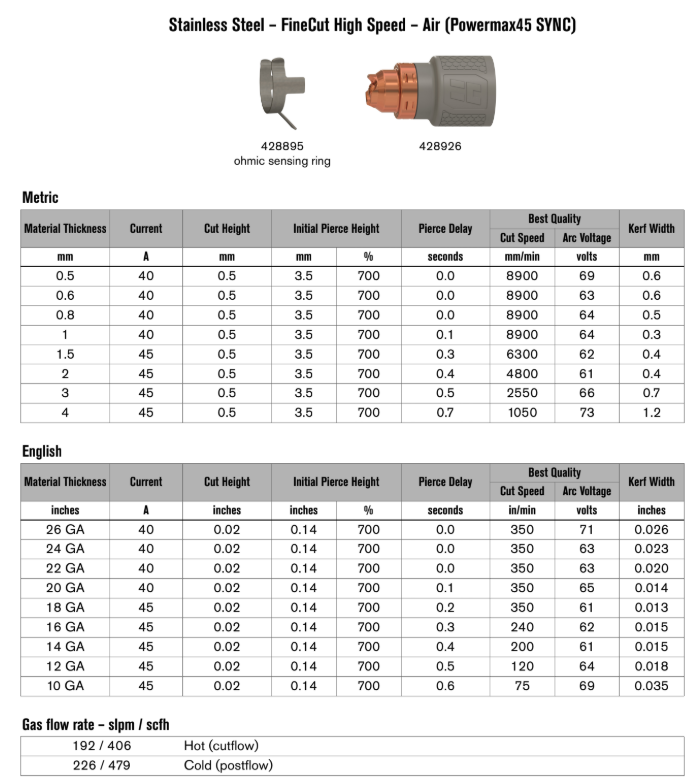

== | ==Cut Charts== | ||

Click "Expand" to see the chart relevant to the tip and material you are working with. | |||

===Fine Cut Tip=== | |||

<div class="toccolours mw-collapsible mw-collapsed"> | |||

<div style="font-weight:bold;line-height:1.6;">Mild Steel - Slow</div> | |||

<div class="mw-collapsible-content"> | |||

[[File:MildSteel-FineCut-LowSpeed-Powermax45.png|border]] | |||

</div></div> | |||

<div class="toccolours mw-collapsible mw-collapsed"> | |||

<div style="font-weight:bold;line-height:1.6;">Mild Steel - Fast</div> | |||

<div class="mw-collapsible-content"> | |||

[[File:MildSteel-FineCut-HighSpeed-Powermax45.png|border]] | |||

</div></div> | |||

<div class="toccolours mw-collapsible mw-collapsed"> | |||

<div style="font-weight:bold;line-height:1.6;">Stainless Steel - Slow</div> | |||

<div class="mw-collapsible-content"> | |||

[[File:StainlessSteel-FineCut-LowSpeed-Powermax45.png|border]] | |||

</div></div> | |||

<div class="toccolours mw-collapsible mw-collapsed"> | |||

<div style="font-weight:bold;line-height:1.6;">Stainless Steel - Fast</div> | |||

<div class="mw-collapsible-content"> | |||

[[File:StainlessSteel-FineCut-HighSpeed-Powermax45.png|border]] | |||

</div></div> | |||

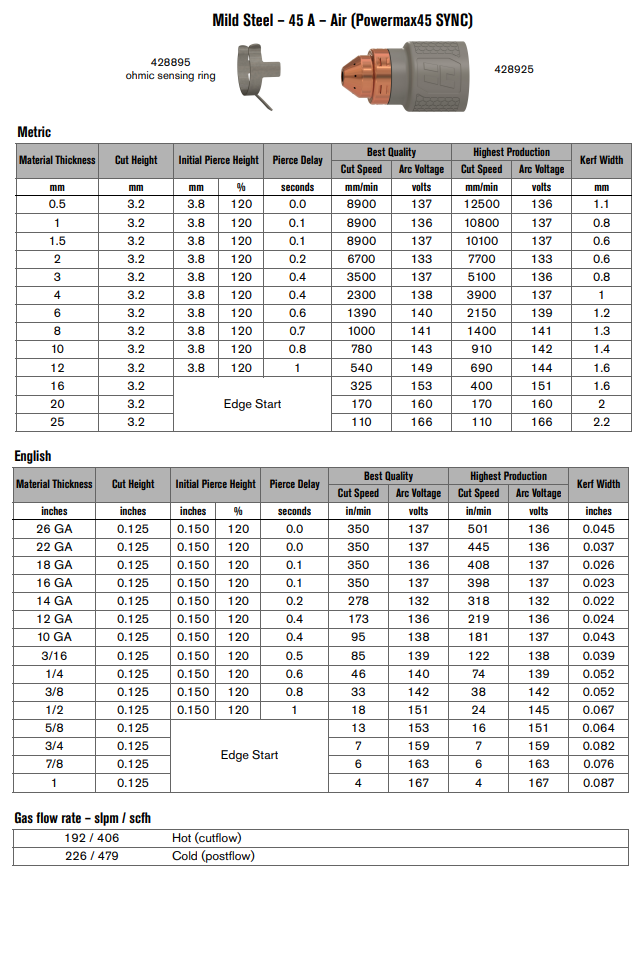

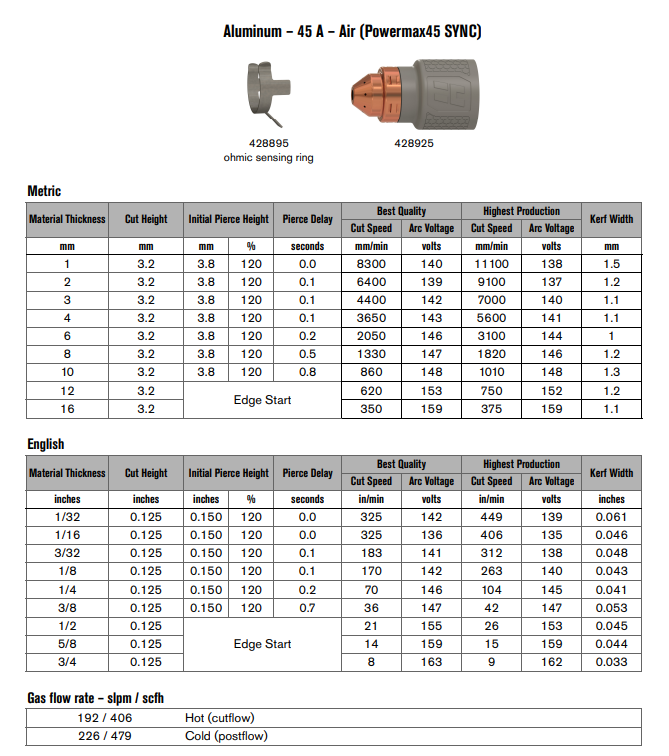

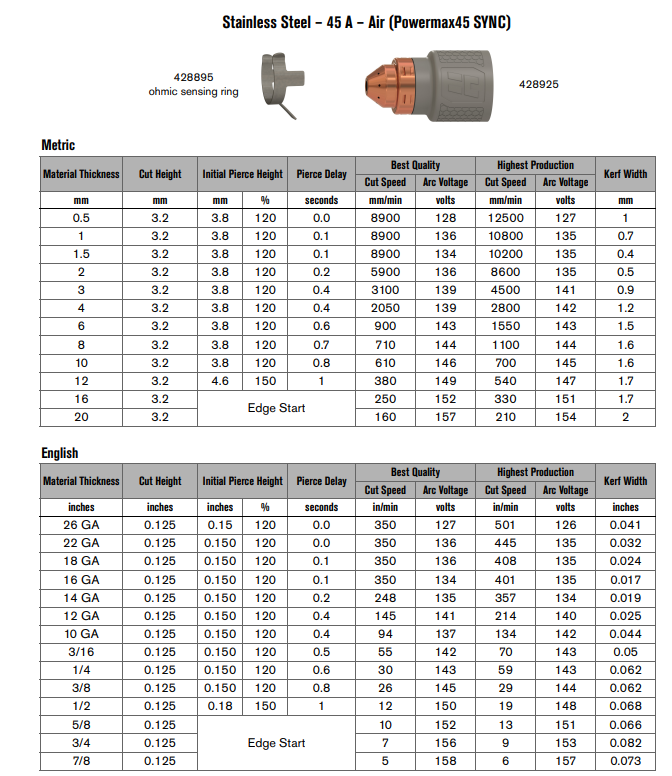

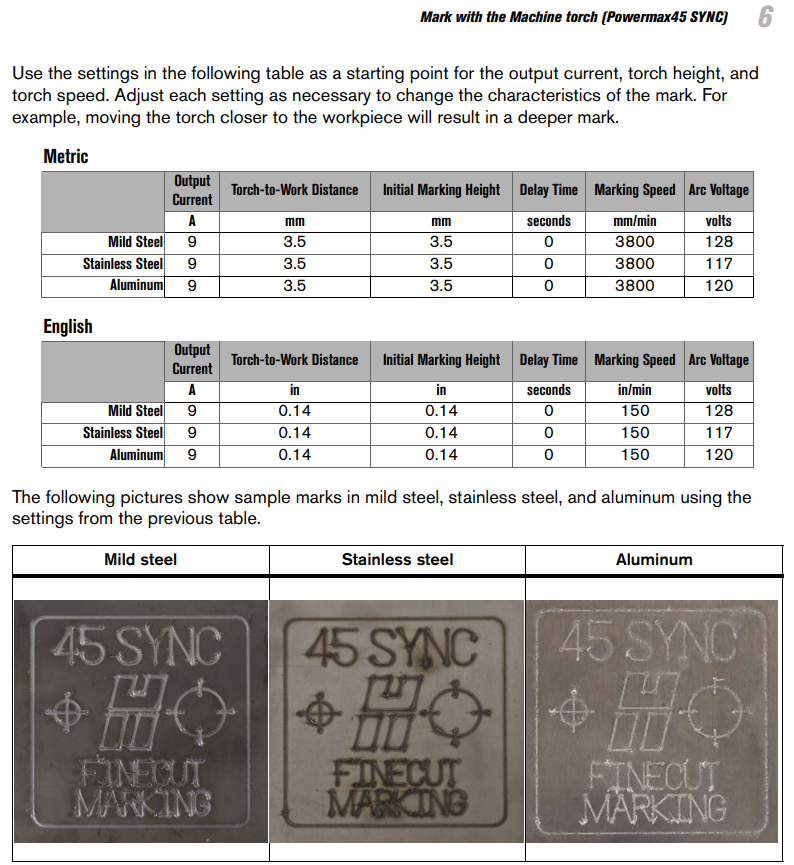

===45A Tip=== | |||

<div class="toccolours mw-collapsible mw-collapsed"> | |||

<div style="font-weight:bold;line-height:1.6;">Mild Steel</div> | |||

<div class="mw-collapsible-content"> | |||

[[File:MildSteel-Powermax45.png|border]] | |||

</div></div> | |||

<div class="toccolours mw-collapsible mw-collapsed"> | |||

<div style="font-weight:bold;line-height:1.6;">Aluminum</div> | |||

<div class="mw-collapsible-content"> | |||

[[File:Aluminum-Powermax45.png|border]] | |||

</div></div> | |||

<div class="toccolours mw-collapsible mw-collapsed"> | |||

<div style="font-weight:bold;line-height:1.6;">Stainless Steel</div> | |||

<div class="mw-collapsible-content"> | |||

[[File:StainlessSteel-Powermax45.png|border]] | |||

</div></div> | |||

<div class="toccolours mw-collapsible mw-collapsed"> | |||

<div style="font-weight:bold;line-height:1.6;">Marking</div> | |||

<div class="mw-collapsible-content"> | |||

[[File:Marking-Powermax45.png|border]] | |||

</div></div> | |||

==Troubleshooting== | ==Troubleshooting== | ||

| Line 40: | Line 196: | ||

==External Resources== | ==External Resources== | ||

* | *[https://www.langmuirsystems.com/fireshare FireShare] - Manufacturer database for downloading and sharing free, cut-ready files. | ||

[[Category: Tool]] | [[Category: Tool]] | ||

[[Category: Metal Shop]] | |||

[[Category: Safety Checkout]] | [[Category: Safety Checkout]] | ||

Latest revision as of 11:46, 24 October 2025

About our machine

- Manufacturer: Langmuir Systems

- Model: CrossFire Pro

- Cutting Area: 48.25” (X) x 33.3” (Y) x 2.75" (Z) + 3” Manual Height Adjustment

- Computer:

- Control Software: FireControl

- Plasma Cutter: Hypertherm Powermax45 Sync Model# 088184

- Max cutting capacity: 5/8" thick steel

Guides and Manuals

- General

- Plasma Safety - Manufacturer's safety warnings for plasma cutting.

- Software

- Cut With FireControl - Manufacturer's guide to software use.

- Fusion Outline (for class)

- User Guides

- Hypertherm45 Sync

- Hardware

Standard Operating Procedures

Safety Precautions

1. Personal Protective Equipment (PPE):

- Wear safety glasses with side shields or a face shield.

- Use flame-resistant gloves and clothing.

- Turn on air filter system

- Turn on exhaust fan

2. Work Area Safety:

- Ensure the work area is clean, dry, and free of flammable materials.

- Maintain adequate ventilation to avoid inhalation of fumes and gases.

- Know the location of the fire extinguisher. Next to the Auto Bay access door.

3. Equipment Safety:

- Inspect the plasma cutter, CNC table, and all connections for damage before use.

- Ensure the plasma cutter is properly grounded.

- Do not operate the equipment if any safety guards or covers are missing or damaged.

Equipment Setup

1. CNC Table Setup:

- Empty Air Compressor of water: Slowly, partially open the ball valve at the base of the air compressor. Allow water to escape. When water stops coming out, close the valve.

- Run Extension Cord for Power

- Power On: Turn on the Langmuir Systems Crossfire Pro CNC table.

- Software Initialization: Launch the CNC control software (e.g.,FireControl) on the connected computer.

- Home the Machine: Use the software to home the machine, ensuring

- the torch is in the correct starting position.

- Material Placement: Securely clamp the material to be cut onto the

- CNC table, ensuring it is flat and properly aligned.

2. Plasma Cutter Setup:

- Power On: Turn on the Hypertherm Powermax 45 SYNC plasma cutter.

- Air Supply: Ensure the air compressor is on and supplying clean, dry air at the recommended pressure (typically 85 PSI).

- Power Setting: Set the Amps to the recommended setting found in the Cut Chart

- Ground Clamp: Attach the ground clamp to the material being cut, ensuring a good electrical connection.

3. Software Configuration:

- Load Design: Import or create the design file in the CNC control software.

- Material Settings: Configure the material type and thickness in the software to match the cutting parameters.

- Cut Parameters: Set the appropriate cut speed, amperage, and pierce height based on the material and plasma cutter specifications.

Operation

1. Pre-Cut Check:

- Verify Material is Grounded

- Test Run: Perform a test run without the plasma cutter on to ensure the torch follows the correct path.

- Safety Check: Ensure all safety equipment is in place and the work area is clear.

2. Start Cutting:

- Initiate Cut: Start the cutting process from the CNC control software.

- Monitor Process: Keep an eye on the cutting process to ensure everything is operating correctly.

- Be prepared to pause or stop the machine if any issues arise.

3. Post-Cut Procedures:

- Power Off Plasma Cutter: Turn off the Hypertherm Powermax 45 SYNC plasma cutter.

- Remove Material: Carefully remove the cut material from the CNC table, ensuring it is cool enough to handle.

- Clean Up: Remove any slag or debris from the CNC table and work area.

- Inspect Cuts: Check the quality of the cuts and make any necessary adjustments to the settings for future cuts.

Maintenance

1. Post Use Maintenance:

- Clean the Table: Remove any metal shavings, dust, or debris from the CNC table. Ensure that the Gantry,Rails and Screws are clean. Apply WD-40 to the screws.

- Inspect Torch: Check the plasma torch for wear and damage. Replace consumables as needed.

- Check Air Filter: Inspect and clean the air filter on the plasma cutter.

2. Weekly Maintenance:

- Lubricate Moving Parts: Apply lubrication to the CNC table’s moving parts as recommended by the manufacturer.

- Inspect Cables and Hoses: Check all cables and hoses for wear, cracks, or damage.

3. Monthly Maintenance:

- Software Updates: Check for and install any updates for the CNC control software.

Emergency Procedures

1. Fire:

- Immediate Action: Use a fire extinguisher to put out the fire if it is safe to do so.

- Evacuate: If the fire cannot be controlled, evacuate the area and call emergency services.

2. Equipment Malfunction:

- Power Off: Immediately turn off the CNC table and plasma cutter.

- Inspect: Inspect the equipment for the cause of the malfunction.

- Report: Report the issue to a supervisor or maintenance personnel.

- Neil Rudnick – neil@portcitymakerspace.com

3. Injury:

- First Aid: Provide first aid if trained to do so.

- Seek Help: Call for medical assistance if the injury is serious.

Documentation

- Report Issues: Document any issues or malfunctions and report them to the appropriate personnel. Neil Rudnick – neil@portcitymakerspace.com

Training

- Operator Training: Ensure all operators are trained on the safe and proper use of the Langmuir

- Systems Crossfire Pro and Hypertherm Powermax 45 SYNC.

- Refresher Training: Provide periodic refresher training to keep operators up-to-date on safety and operational procedures.

Important Notes

- Use welding goggles or a welding helmet when using this tool. It creates bright arcs that can damage your eyes.

- Use gloves when handling materials. Edges can be sharp, and recently cut metals will be hot.

- When pieces are cut free from the main material, they may shift and fall into the table, or they may tilt upwards and potentially collide with the nozzle as it moves. Stop the machine if it is at risk for colliding in this way.

- Check the manual for the plasma cutter to determine which nozzle and what settings to use for your material type and thickness.

- The water table needs to be changed every 1-2 weeks depending on usage.

- When draining, DO NOT allow metal particulate to go down the utility sink. Filter it out with a cheese cloth or scrap fabric and toss in the garbage.

Consumables

Cut Charts

Click "Expand" to see the chart relevant to the tip and material you are working with.

Fine Cut Tip

45A Tip

Troubleshooting

External Resources

- FireShare - Manufacturer database for downloading and sharing free, cut-ready files.