CNC Plasma Cutter: Difference between revisions

Jump to navigation

Jump to search

mNo edit summary |

added reference charts for cut parameters, links to Hypertherm45 manuals |

||

| Line 22: | Line 22: | ||

**[https://www.langmuirsystems.com/software/sheetcam CAM with SheetCAM] | **[https://www.langmuirsystems.com/software/sheetcam CAM with SheetCAM] | ||

**[https://www.langmuirsystems.com/thc/guide LS-Torch Height Controller Guide] | **[https://www.langmuirsystems.com/thc/guide LS-Torch Height Controller Guide] | ||

*Hypertherm45 Sync | |||

**[https://drive.google.com/file/d/1WIbmiCK-XQeKN51yuDPLWSBvQOnZUsa-/view?usp=drive_link Operator Manual] | |||

**[https://drive.google.com/file/d/1j29hIJ0AO5Y6iPPt0vm574MrJJh7Dy2C/view?usp=drive_link Cut Charts Guide] | |||

**[https://drive.google.com/file/d/1KPcf_eG64azRM46mJGcRapfbDzzs1fKw/view?usp=drive_link Mechanized Cutting Guide] | |||

==Important Notes== | ==Important Notes== | ||

| Line 33: | Line 38: | ||

==Consumables== | ==Consumables== | ||

*[https://www.hypertherm.com/en-US/hypertherm/powermax/powermax45-sync/#torches-and-consumables Torch tips] | *[https://www.hypertherm.com/en-US/hypertherm/powermax/powermax45-sync/#torches-and-consumables Torch tips] | ||

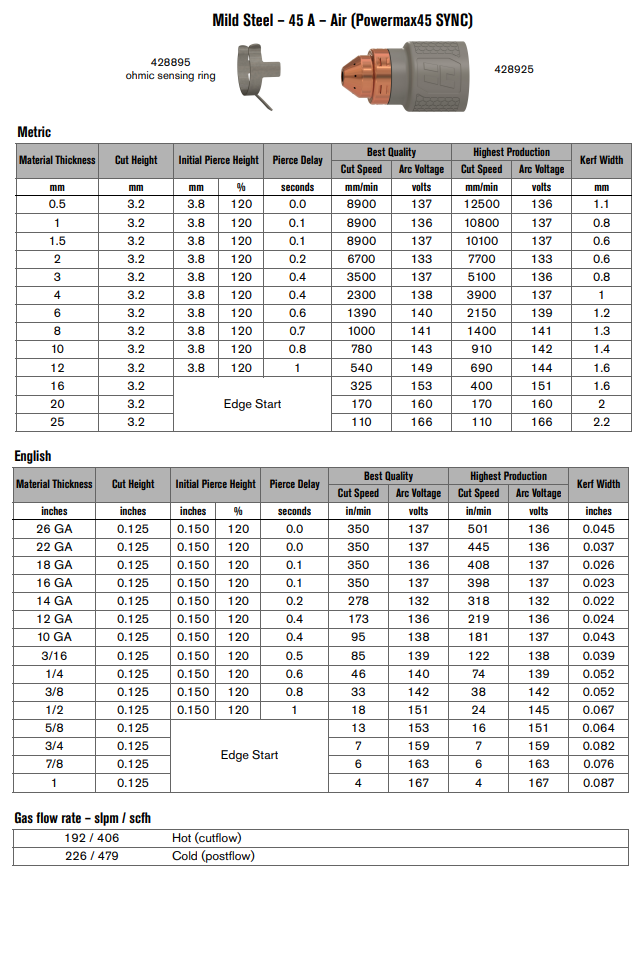

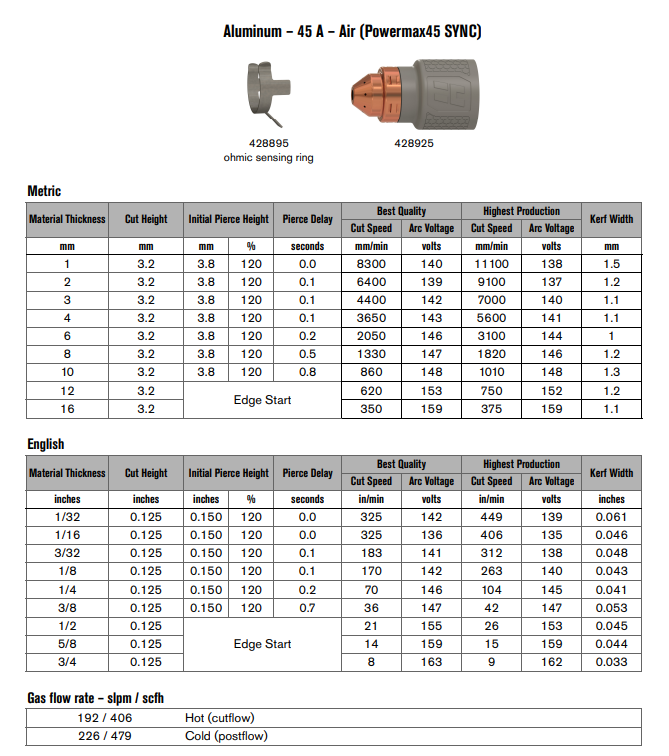

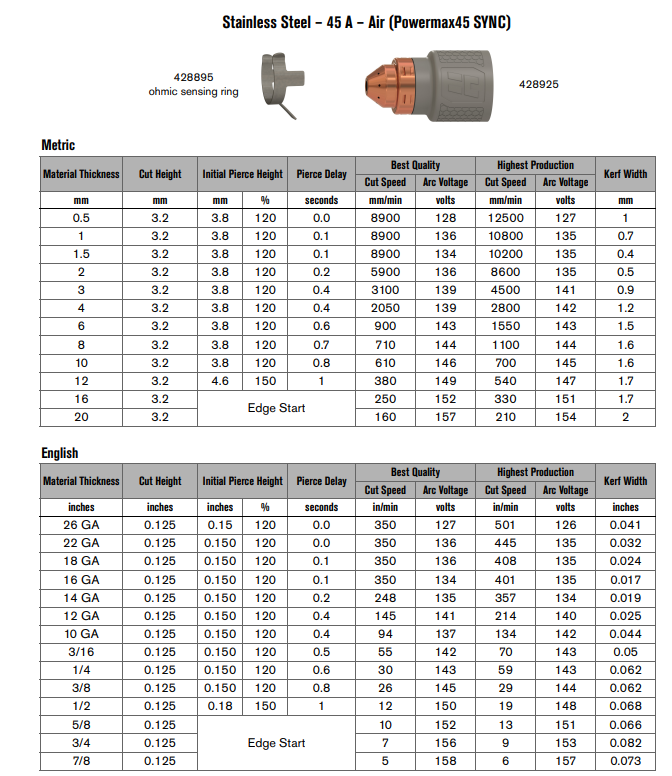

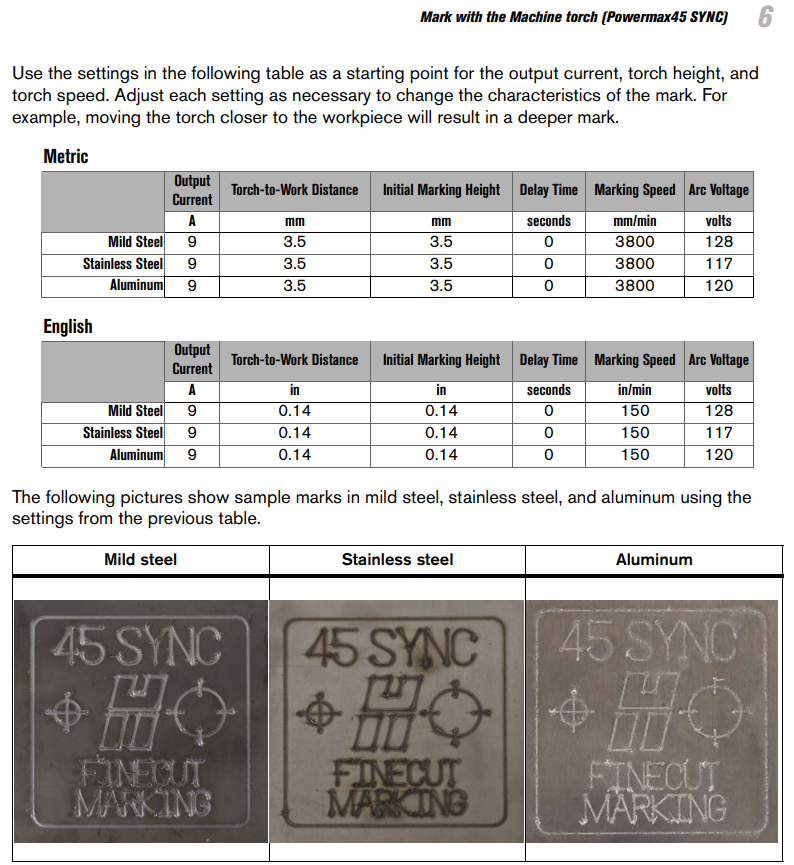

==Cut Charts== | |||

[[File:MildSteel-Powermax45.png|border]] | |||

[[File:Aluminum-Powermax45.png|border]] | |||

[[File:StainlessSteel-Powermax45.png|border]] | |||

[[File:Marking-Powermax45.png|border]] | |||

==Troubleshooting== | ==Troubleshooting== | ||

Revision as of 12:21, 22 June 2025

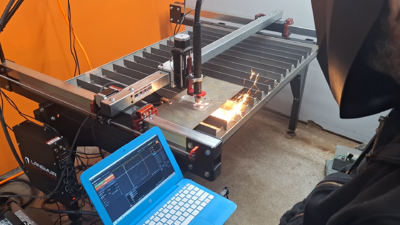

About our machine

- Manufacturer: Langmuir Systems

- Model: CrossFire Pro

- Cutting Area: 48.25” (X) x 33.3” (Y) x 2.75" (Z) + 3” Manual Height Adjustment

- Computer:

- Control Software: FireControl

- Plasma Cutter: Hypertherm Powermax45 Sync Model# 088184

- Max cutting capacity: 5/8" thick steel

Guides and Manuals

- Plasma Safety - Manufacturer's safety warnings for plasma cutting.

- Cut With FireControl - Manufacturer's guide to software use.

- CrossFire Pro Assembly Guide

- Manufacturer User Guides

- Hypertherm45 Sync

Important Notes

- Use welding goggles or a welding helmet when using this tool. It creates bright arcs that can damage your eyes.

- Use gloves when handling materials. Edges can be sharp, and recently cut metals will be hot.

- When pieces are cut free from the main material, they may shift and fall into the table, or they may tilt upwards and potentially collide with the nozzle as it moves. Stop the machine if it is at risk for colliding in this way.

- Check the manual for the plasma cutter to determine which nozzle and what settings to use for your material type and thickness.

- The water table needs to be changed every 1-2 weeks depending on usage.

- When draining, DO NOT allow metal particulate to go down the utility sink. Filter it out with a cheese cloth or scrap fabric and toss in the garbage.

Consumables

Cut Charts

Troubleshooting

External Resources

- FireShare - Manufacturer database for downloading and sharing free, cut-ready files.